MIL-DTL-6484D

made with atmospheric pressure or room temperature differing materially from the above values, proper allowance shall

be made for the difference from the specified condition.

4.3 Qualification inspections.

4.3.1 Prior qualification. Unless otherwise specified by the procuring activity, light assemblies qualified to

earlier issues of this specification, light assemblies which have not passed a qualification test, or which have passed the

qualification tests but have been modified in any manner, shall satisfactorily pass a qualification test prior to acceptance.

4.3.2 Sampling instructions. The qualification test samples shall consist of three complete assemblies of each

manufacturer's part number upon which qualification is desired. Samples shall be identified as required and forwarded

with the certified test procedure and results to the activity responsible for qualification, designated in the letter of

authorization from that activity. (see 6.3).

4.3.3 Qualification test methods. The qualification test shall consist of all the tests listed herein. The test

samples shall be allocated as specified in Table I and tested in the order listed.

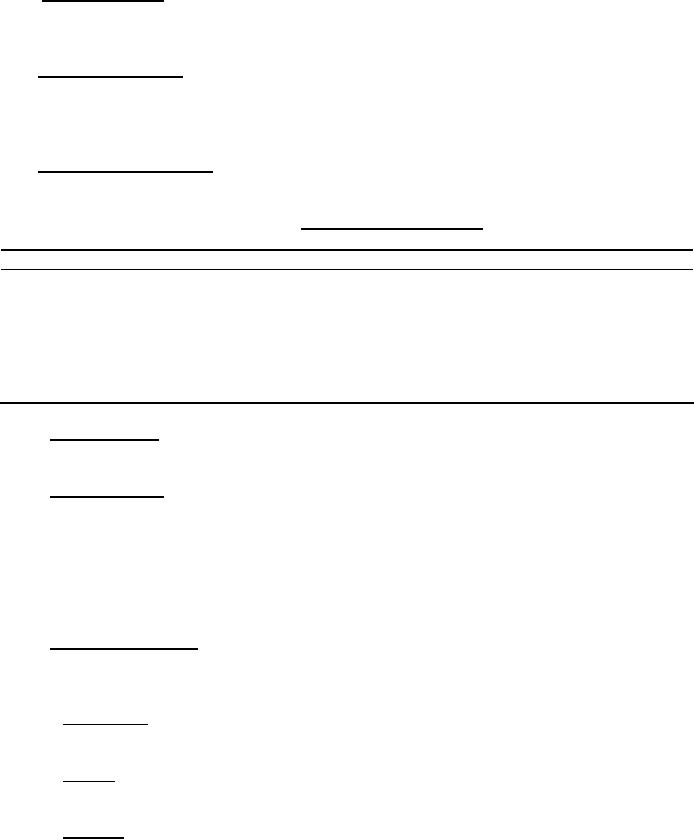

TABLE I. QUALIFICATION TESTS

Sample No. 1

Sample No. 2

Sample No. 3

a. Examination of product

a. Dielectric

Rough handling

b. Operation

b. Sand and dust

c. Photometric

c. Humidity

d. Low temperature

d. Salt fog

e. Temperature rise

f. High temperature

g. Vibration

4.3.3.1 Photometric test. The sample light assembly shall be subjected to photometric tests to determine

compliance with the light distribution requirements specified in the applicable specification sheet or MS drawing.

4.3.3.2 Low temperature. The light assembly base shall be solidly mounted on a metal stand or table in the cold

chamber. The light assembly, complete with cord, shall be mounted in its base and subjected to a temperature of -37�C

for a period of 6 hours and then operated at this temperature. The test shall also consist of pulling the light out of its

mounting base and the pulling force to remove the light out of the mounting base shall be greater than 1 and less than 5

pounds. The cord shall then be stretched to a length of 5 feet and held for 2 hours. The cord when released, shall

immediately return to within 5 percent of its original coiled length. Failure of the light assembly or cord in this test

shall be cause for rejection.

4.3.3.3 Low temperature tests. If the light assembly and cord satisfactorily passes the tests specified in 4.3.3.2,

the light assembly shall be reinstalled in the base and subjected to the low temperature tests, method 502.4, procedure I,

MIL-STD-810. Operation of the equipment shall be as specified in the following paragraphs:

4.3.3.3.1 Rotation test. The light shall be grasped by the case and rotated in the swivel mount 90 degrees to the

right and then 90 degrees to the left of its installed position. The light shall be turned five times in each direction.

4.3.3.3.2 Tilt test. If the light satisfactorily meets the rotation test without failure, it shall be tilted up 45 degrees

and then down 45 degrees with the mounting surface of the base. The light shall be tilted five times in each direction.

4.3.3.3.3 Cord test. If the light assembly satisfactorily meets the tilt test without failure, it shall be pulled out of

the base and reinstalled three times. It shall then be removed and the cord stretched to approximately 3 feet. The light

assembly or cord shall not be damaged in this test. Failure of the cord to return to its coiled position at the conclusion of

the test will not be considered a failure, provided the cord recoils when its temperature is returned to room temperature.

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business