MIL-DTL-25866C

provided that the material meets or exceeds the operational and maintenance requirements, and

promotes economically advantageous life cycle costs.

4. VERIFICATION

4.1 Classification of inspections. The inspection requirements specified herein are

classified as follows:

a. First article testing (see 4.2).

b. Conformance inspection (see 4.3).

4.2 First article testing.

4.2.1 First article test samples. The first article test samples shall consist of three lights

representative of the production equipment. They shall be tested in a laboratory designated by

the procuring activity or, when so stated in the contract, at the contractor's plant under the

supervision of the procuring activity.

4.2.2 First article tests. First article tests shall consist of all tests described under 4.5 and

shall be tested in the order show in table II.

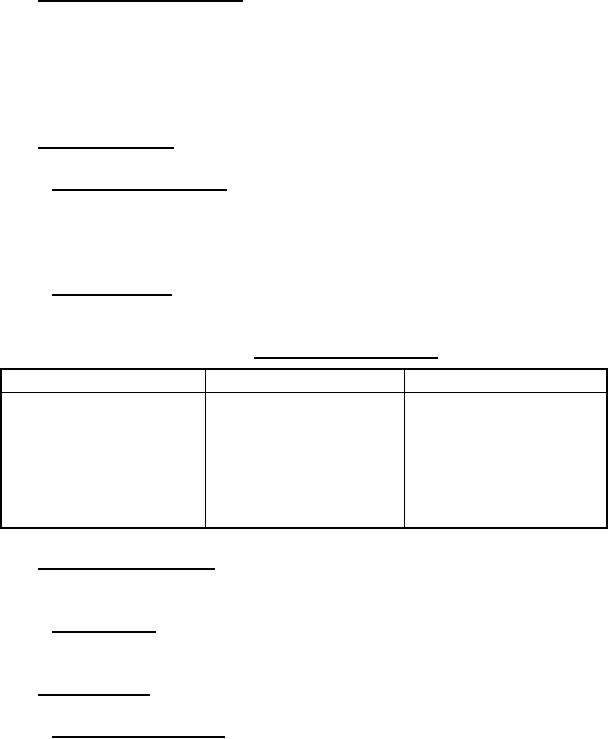

TABLE II. First article test sequence.

Sample number 1

Sample number 2

Sample number 3

Examination of product

Examination of product

Examination of product

Illumination

Vibration

Humidity

(photometric)

Acceleration

Salt spray

High temperature

Shock

Sand and dust

Low temperature

Underwater operation

Explosion proof

Altitude

Portability

4.3 Conformance inspection. Conformance inspection shall consist of the individual

test.

4.3.1 Individual test. Each light shall be subjected to the examination of product

described in 4.5.1 and 4.5.1.1.

4.4 Test conditions.

4.4.1 Atmospheric conditions. Unless otherwise specified, the tests shall be made at an

atmospheric pressure of approximately 29.92 inHg and at room temperature of approximately

77 °F (25 °C). Where tests are made with pressure or temperature differing materially from

these values, proper allowance shall be made for the difference from the specified condition.

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business