MIL-DTL-3976F

2.4 Order of precedence. In the event of a conflict between the text of this document and

the reference cited herein, the text of this document takes precedence. Nothing in this document,

however, supersedes applicable laws and regulations unless a specific exemption has been obtained.

3. REQUIREMENTS

3.1 First article. When specified, (see 6.2) a sample shall be subjected to first article

inspection in accordance with paragraph 4.3.

3.2 Materials. Materials shall be as specified herein and in referenced specifications,

standards, and drawings (see 4.6.1).

3.2.1 Solder. Unless otherwise specified, solder shall be of a composition conforming to Sn

50 or Sn 60 of J-STD-006 (see 4.6.1).

3.2.2 Lampholder boot rubber. Physical properties of the rubber used in the lampholder

boot shall be as specified below and in table I (see 4.6.1):

a.

Shore A durometer hardness: 50 ± 5

b.

Minimum tensile strength: 1500 pounds per square inch (psi)

c.

Minimum ultimate elongation: 3.5 percent (%)

d.

Resistance to oil aging: 0 120% volume change

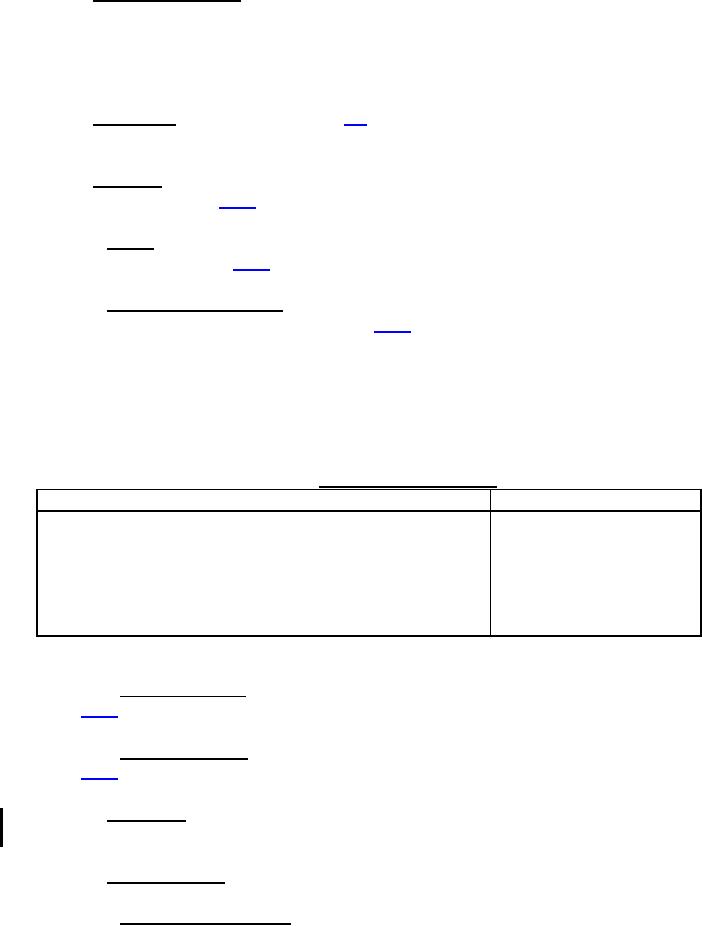

TABLE I. Material property values.

Physical property

Test

Resistance to heat aging: 70 hours, 158º F*

ASTM D573

Compression set: 50%, after 22 hours at 158º F*

ASTM D395, method B

Resistance to ozone at 50 parts per hundred million (pphm) ASTM D1149

at 100º F* for 7 days

Low temperature brittleness at -67º F*

ASTM D2137, method A

Resistance to water

ASTM D471

NOTES: F*- Degrees Fahrenheit

3.2.2.1 Lampholder door. Lampholder door shall be die cast aluminum as specified in

3.2.3 (see 4.6.1).

3.2.2.2 Lampholder plate. Lampholder plate shall be die cast aluminum as specified in

3.2.3 (see 4.6.1).

3.2.3 Aluminum. Die cast parts shall be of an aluminum alloy conforming to UNS A03600,

A03800, A13800, or A14130 per ASTM-B85/B85M.

3.2.4 Lens assemblies.

3.2.4.1 Blackout lens assembly.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business