MIL-DTL-14465F

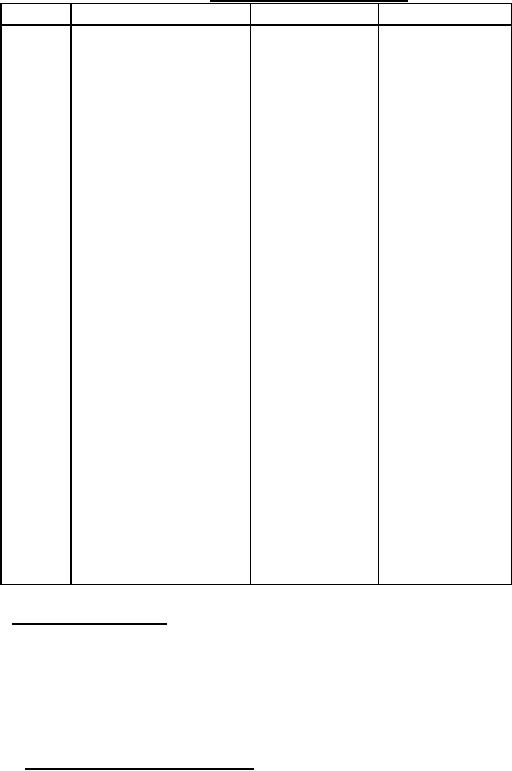

TABLE VI. Order of first article testing.

Sample

Test

Requirement

Verification

1

Functioning

3.4.1

4.2.4.1

Sealed-beam lamps

3.4.2

4.2.4.2

Blackout driving light

3.4.4

4.2.4.4

Blackout marker light

3.4.3

4.2.4.3

Vibration resistance

3.7.3

4.2.7.3

Functioning

3.4.1

4.2.4.1

Waterproofness

3.7.2

4.2.7.2

Shock resistance

3.7.4

4.2.7.4

Functioning

3.4.1

4.2.4.1

Waterproofness

3.7.2

4.2.7.2

2

Functioning

3.4.1

4.2.4.1

Sealed-beam lamps

3.4.2

4.2.4.2

Blackout driving light

3.4.4

4.2.4.4

Blackout marker light

3.4.3

4.2.4.3

Corrosion resistance

3.7.6

4.2.7.6

3

Functioning

3.4.1

4.2.4.1

Sealed-beam lamps

3.4.2

4.2.4.2

Blackout driving light

3.4.4

4.2.4.4

Blackout marker light

3.4.3

4.2.4.3

Functioning

3.4.1

4.2.4.1

4

Functioning

3.4.1

4.2.4.1

Sealed-beam lamps

3.4.2

4.2.4.2

Blackout driving light

3.4.4

4.2.4.4

Blackout marker light

3.4.3

4.2.4.3

Fungus resistance

3.7.5

4.2.7.5

Functioning

3.4.1

4.2.4.1

Waterproofness

3.7.2

4.2.7.2

4.2.2 Inspection conditions. Unless otherwise specified, all inspections shall be

performed under the following ambient conditions (see 6.2).

a. Temperature: 25 ± 10°C.

b. Atmospheric pressure: Site pressure.

c. Relative humidity: Uncontrolled room ambient.

4.2.2.1 Laboratory driving light aiming. Proper aiming of the driving lights (without

lens) for laboratory testing shall be as follows:

a. The greatest light intensity of the lower beam of the sealed-beam lamp shall fall

690 mm below the horizontal line on a screen placed 7.6 m from the lamp source.

b. Lateral adjustment shall be such that the center of the highest light intensity on the

screen shall be straight ahead with a tolerance of ±76 millimeters (mm) on either

side of the vertical plane.

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business